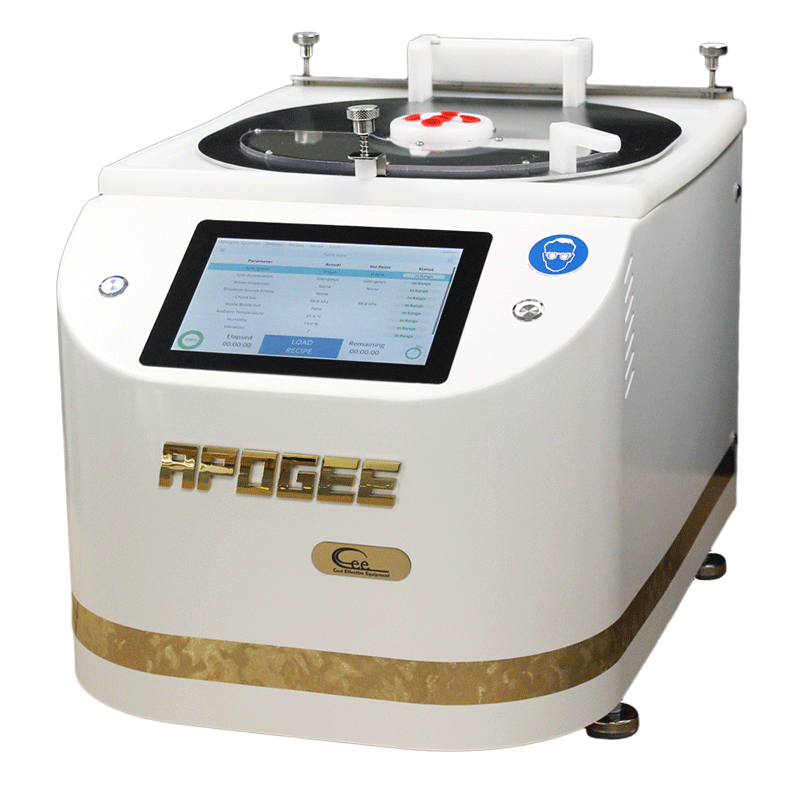

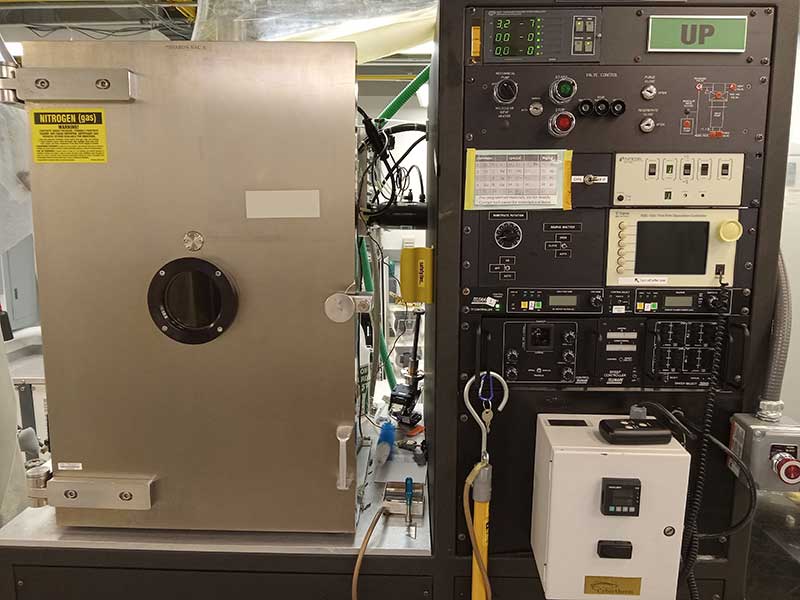

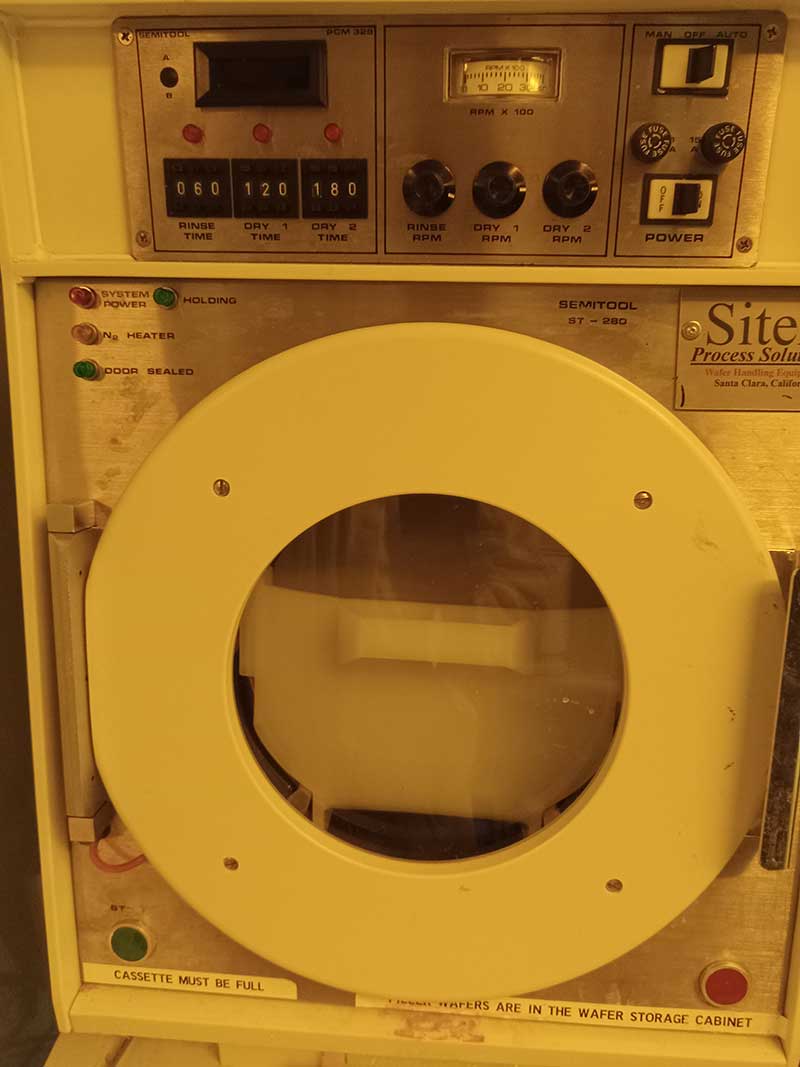

The CNSE Innovation Lab is a collection of academic cleanrooms and labs that provide partners with strategic support through technology acceleration, proof of concept, pilot prototyping, and test-bed integration support for “next generation” nanotechnology research activities. Projects processed in these labs tend to focus on traditional and emerging applications in the areas of nanoelectronics, microsystems, nanobioscience, and clean energy.

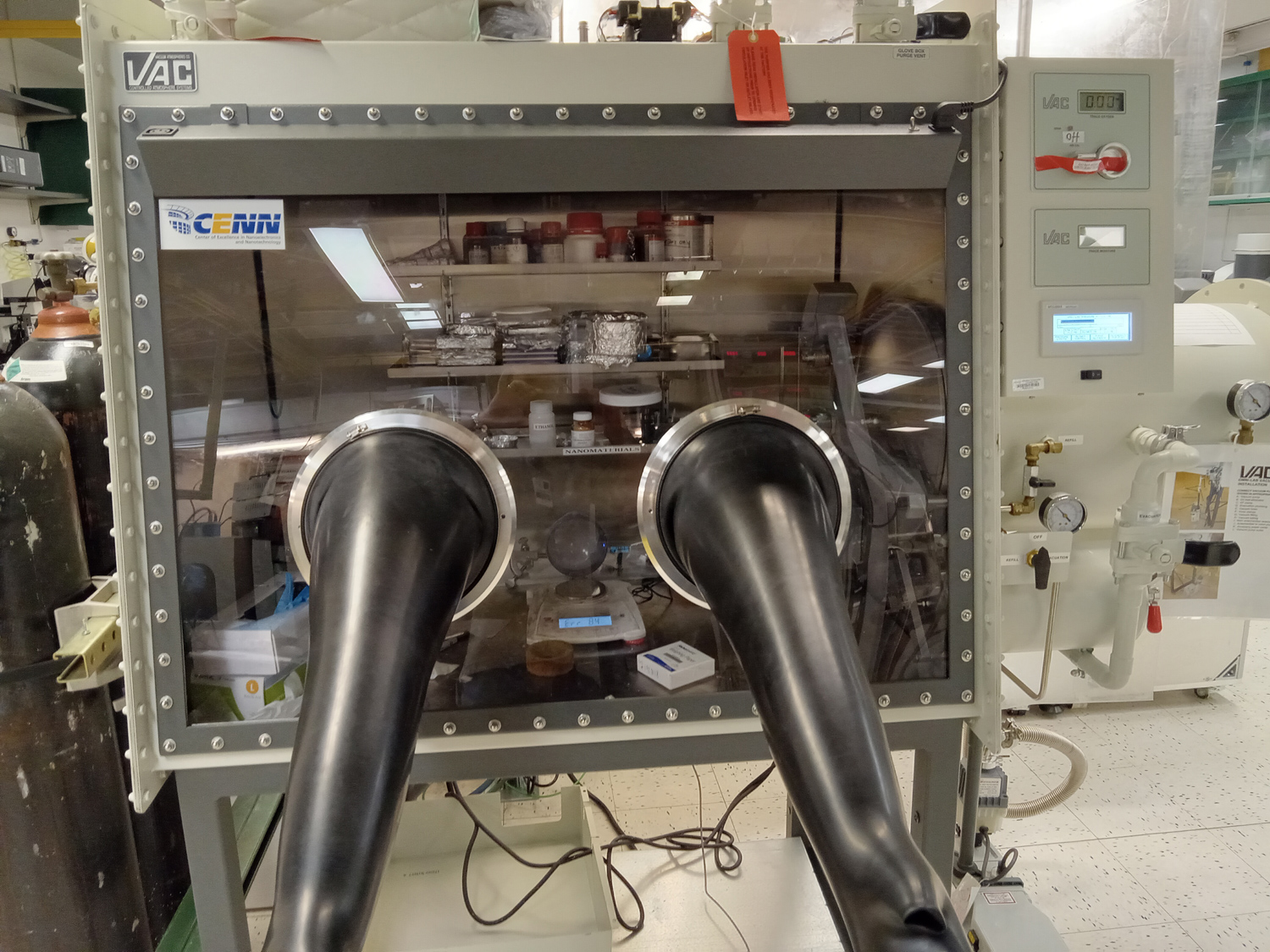

The CNSE Innovation Lab contains a full complement of leading-edge tools to convert ideas into reality with process capabilities that include: thin film deposition, wet etch, deep reactive ion etch, dry etch, wafer bonding, polymer processing, wafer patterning, handling of multiple wafer sizes up to 200mm and materials, rapid thermal anneal, and ion implantation. Projects processed within these labs not only have access to CNSE faculty subject matter experts, but also the co-located semiconductor supply chain for rapid manufacturing scale up.

See our current tool catalog. If there is something you wish to use, but do not see, please ask.

For more information on our engagement models or to schedule time to tour the facility please contact the CNSE Innovation Lab Manager Bryant Colwill at bcolwill@albany.edu.

Examples of some of these devices and subsystems include:

- MEMs

- BioMEMS

- RF MEMS

- Microfluidics

- Micro-optics

- NanoBio

- Nano and micro technology

- 3-D wafer processing

Device and Micro System Simulation and Modeling

Micro Systems and devices are first created by utilizing state-of-the-art simulation and modeling tools which include IntelliSuite and ANSYS.

Mask Layout

After simulation and modeling, the final designs of the devices are laid out using L-Edit to produce photo masks. L-Edit is a VLSI design tool; it is flexible enough to do micromachining design, printed circuit board layout and other CAD work.

CNSE's professors and professional staff welcome the challenge of developing unique devices and processes with our partners.

Processing Capabilities

- 100 to 200 mm Substrates

- - Silicon, Glass, Ceramic, Polymer

- Standard and Custom Processes Supported

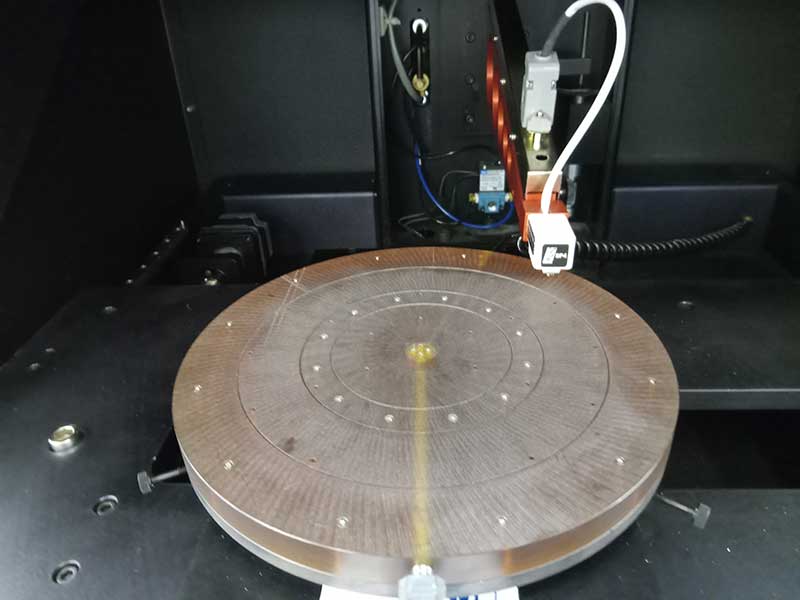

- Thin Film Deposition

- Patterning

- Etching

- Bonding

- CMP

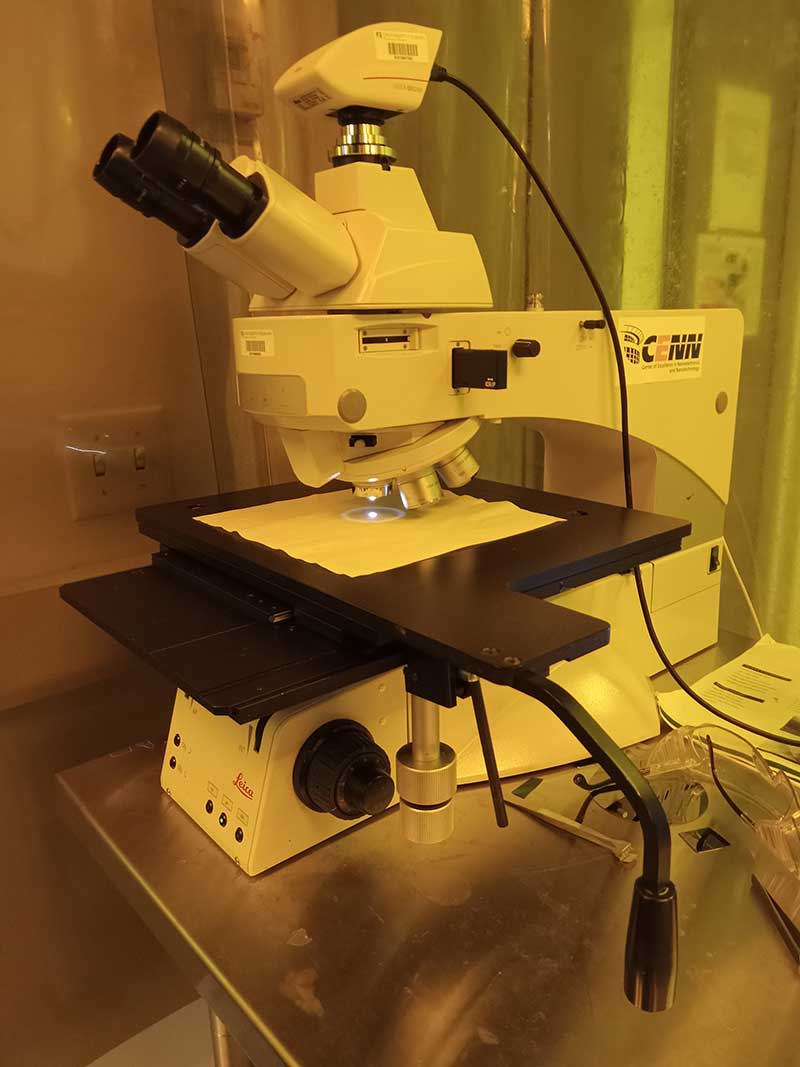

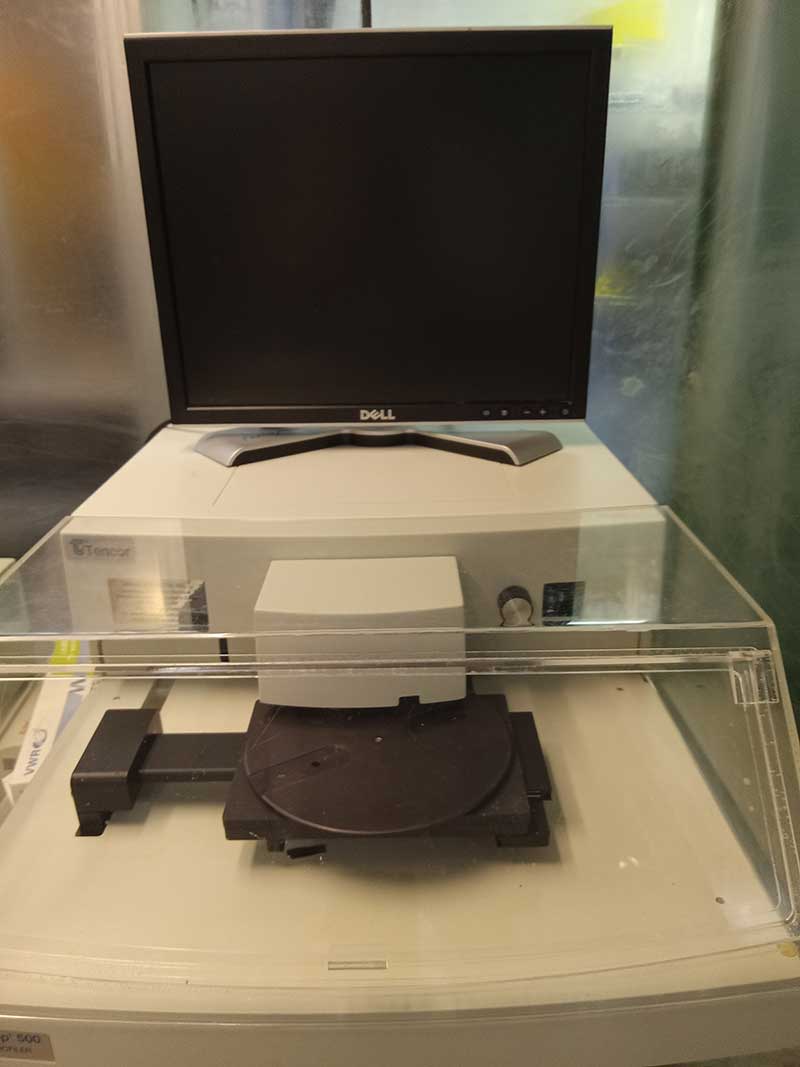

- Complete Metrology Suite