UAlbany Researchers Receive Patent for Novel PFAS Removal System

By Erin Frick

ALBANY, N.Y. (June 25, 2024) — University at Albany’s John Paccione and David Dziewulski have patented the design of a new system to treat water for PFAS — synthetic chemicals known to contaminate ground and surface waters. PFAS (short for per- and polyfluoroalkyl substances), are difficult to decompose, linger in the environment and pose a threat to both environmental and human health.

The novel system is designed to be efficient, scalable and adaptable, with potential to treat water and wastewater from manufacturing facilities that use PFAS, aide in the disposal of foams used to extinguish liquid fires, and remove harmful chemicals from drinking water. The system can be scaled from bench trials up to municipal drinking water facilities.

Paccione is an assistant professor who holds dual appointments in the Department of Environmental Health Sciences at the School of Public Health and the Department of Environmental and Sustainable Engineering at the College of Nanotechnology, Science, and Engineering. Dziewulski is an associate research professor in the Department of Environmental Health Sciences.

"PFAS have gained wide recognition as an emerging public health concern," said UAlbany’s Thenkurussi (Kesh) Kesavadas, vice president for research and economic development. "We know that once these pernicious chemicals enter the environment, they can accumulate and spread through water and soil. Removing PFAS from waste streams is critical to protecting human and ecosystem health.

"This new patent marks an important development in improving the way we could mitigate the spread of PFAS into the environment and reduce human exposure and harmful outcomes. This work is a prime example of how UAlbany researchers are translating lab research into innovative systems with direct benefits for human health and societal well-being."

PFAS Primer

Commonly called "forever chemicals," PFAS are found in industrial and consumer products including food packaging, nonstick cookware, firefighting foams, stain-resistant fabrics and many plastics. PFAS enter the environment via industrial discharge, runoff from firefighting foams and leaching from landfills. The strong chemical bonds that make PFAS-containing products resistant to water and grease also allow them to persist for long periods in the environment and in living organisms.

Studies looking at impacts on human health have linked PFAS exposure to certain cancers, elevated cholesterol, immune suppression, hormone disruption and ill effects on reproductive and developmental processes. Due to bioaccumulation, even low levels of PFAS exposure can cause harm.

Optimizing PFAS Removal

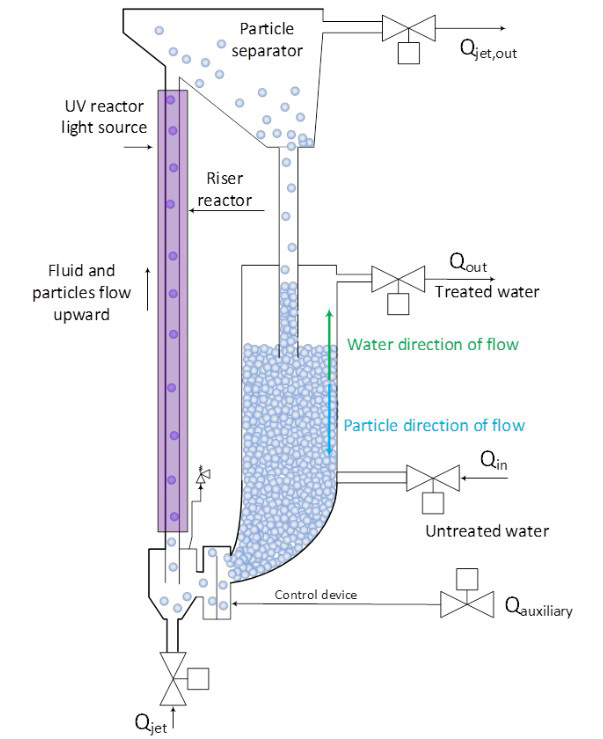

"Most methods for treating water for PFAS use a material such as activated carbon to adsorb, or take up, the target compounds from water to make it cleaner and safer,” said Paccione. "This requires the used adsorbent material to be periodically disposed of or regenerated, creating waste or using more energy. The removal and decomposition processes also typically happen separately from water treatment, which is inefficient."

The new design improves on existing methods of PFAS removal in several ways:

- It allows for PFAS removal and decomposition to be completed at the water treatment site.

- The system is designed to better accommodate variations in flow rate and volume, to optimize overall efficiency.

- By employing a reusable adsorbent, the system reduces waste byproducts.

"Our new process uses a novel fluid-particle contact system to both adsorb and decompose PFAS at the water treatment site using a process called photocatalysis. The process occurs in two steps. First, the PFAS molecules attach (adsorb) to a solid particle of photocatalytic material. Next, the photocatalytic material with PFAS attached is irradiated with UV light, causing the PFAS to decompose.

"This process will hopefully allow treatment operators to run the equipment without regenerating the adsorbent at another location or producing a stream of PFAS concentration that needs further treatment."

Next Steps

"Progressing the concept from design to product depends on the feasibility of using UV light as a way to decompose the adsorbed compound," said Paccione. "We are currently engaging materials scientists to see if their photocatalysts could be used in our reactor. As we learn more, we will then design a lab-scale system from which we will collect data and develop a scalable design for field use. Our eventual goal is to develop a piece of equipment that can be scaled up to treat from hundreds to millions of gallons of water per day."

The patent is owned by Health Research Incorporated. Current research partners include industrial companies that develop photocatalyst materials and adsorbents as well as academic institutions that are at the edge of materials research and development.